Clothing X-Ray Inspection Services

Clothing quality x-ray inspection & quality checks for clothes and textiles.

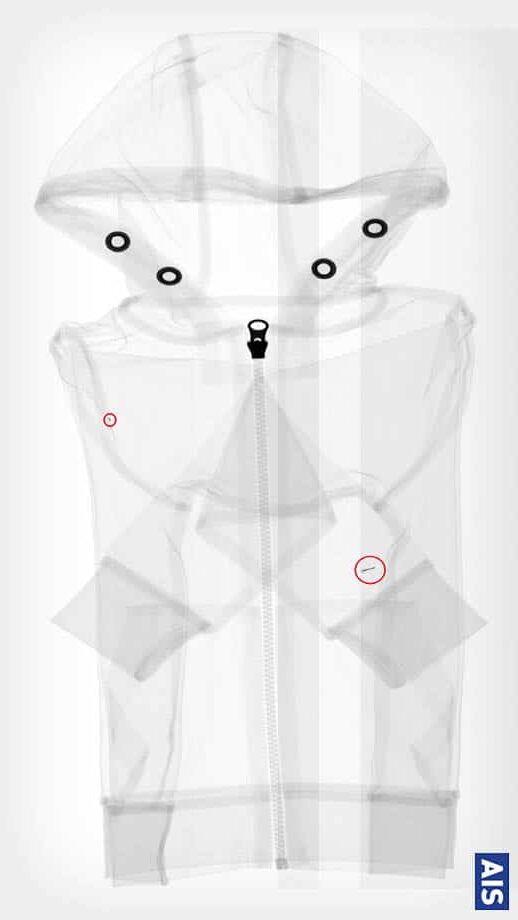

Clothing quality x-ray inspection is the most accurate method of carrying out quality checks on garments or textile goods including rapid detection of needles and potentially dangerous parts.

AIS’ highly trained technicians are on-hand to provide a rapid response to potential clothing recalls and to put your inspected garments safely back into distribution as fast as possible.

Why is clothing quality inspection important?

Consumer safety and satisfaction is essential in the clothing and fashion industry. Faster production speeds increase the likelihood of defects yet common faults such as a broken needle in the seam could be devastating to your brand.

Premium clothes brands manufactured outside the UK may also be subject to less stringent clothing quality inspection and quality checks prior to import. AIS’ fast and efficient clothing quality x-ray inspection services can help quickly and reliably determine the safety of your garments and textiles.

Years’ Expertise

Anomalies Identified

Avoid a costly recall with our clothing quality x-ray inspection services

A needle left in clothes during the manufacturing process is considered a critical defect that poses a threat to consumer safety.

Comprehensive detection

Identify defects without damaging goods

Trusted by clients

90% of inspections are repeat business

ISO 9001 certified

Accredited for our Quality Management System

Certified since 1999

Europe’s first ISO-certified X-ray inspection service

Fast and cost-effective x-ray clothing quality inspection & checks

X-ray inspection of clothing quality is provided on a per-item basis and at very low cost.

Furthermore, it is not usually necessary to unpack clothes and textiles to detect foreign objects and a range of common faults.

What can our clothing and textile quality x-ray inspection service detect?

- Needles or other dangerous metal fragments

- Missing or broken zips, buckles, buttons and fastenings

- Incorrectly sewn items

- Missing parts such as clothing tags and care labels

Our textile and clothing inspection services is available at the end of the manufacturing process or at any stage of product recall.

Why choose us?

Clothes & Apparel FAQs

What clothing quality checks can we provide?

Clothing quality inspection can be carried out at various stages of the manufacturing process: pre-production, in-line and post-production. At AIS, we usually provide an inspection service at the end of the manufacturing process, and often for brands imported to the UK.

Our x-ray inspection equipment can quickly and reliably scan for internal or hidden defects within clothes and seams that may pose a threat to consumer safety:

- sewing needles or metal fragments

- missing or broken zippers and fastenings

- missing or broken accessories

- missing labels

- poor quality stitching

- damaged packaging

Please contact us for a fast and confidential assessment for your particular items and problem.

What other types of clothing quality inspection are available?

Big brand fashion labels will use a plethora of additional Quality Control tools and visual inspection methods to a strict set of guidelines, to ensure their brand reputation is upheld:

- fabric quality and conformance

- garment shape and size

- print and pattern alignment

- fastenings, zippers and accessories

- labelling and packaging

However this level of assessment may be out of the reach of smaller brands and UK imports, who may be looking for a fast and efficient quality inspection service to help ensure that garments with a critical defect do not reach consumers.

What type and size of things can AIS detect?

As a general statement, x-ray can identify anything which has a reasonable absorption differential to the product in which it is surrounded. Typically, we detect foreign objects such as metal and glass fragments or higher density plastics and rubber compounds.

The size of object that we can identify is influenced by the density and size of the contaminant and the product, the position of the contaminant within the pack, and the type of packaging.

Detection of missing items and quality concerns is subject to similar factors.

Find out more about our highest resolution scanner, the Micron Scan.

We will always give a clear and honest appraisal of what is achievable and be prepared to demonstrate that to you at any time.

Request a Free Sample Inspection for AIS to evaluate your product and problem.

How long does it take to inspect the product?

The inspection time is dependent on the target defect or contaminant, the product and pack size, if it can be inspected in a case or has to be stripped from the case, re-shrunk wrapped etc.

A pallet can be as quick as 5 minutes or as long as two hours.

Request a Free Sample Inspection for AIS to evaluate your product and the likely timescale required for your particular problem.

You can also call us – we can often evaluate the issue on the phone.

Can I hire x-ray inspection equipment?

Yes, some of our customisable x-ray inspection systems and metal detectors are available to rent at your premises. These can be hired, subject to availability, on flexible contract periods – usually for an immediate or short term requirement.

Find out more about X-Ray Inspection Equipment Hire.

Request free sample inspection

Free, immediate and confidential evaluation

Email Us

sales@aisx-ray.com

Call Us

+44 (0)1933 674030

Opening Hours

8am to 5pm – Monday to Friday (GMT)