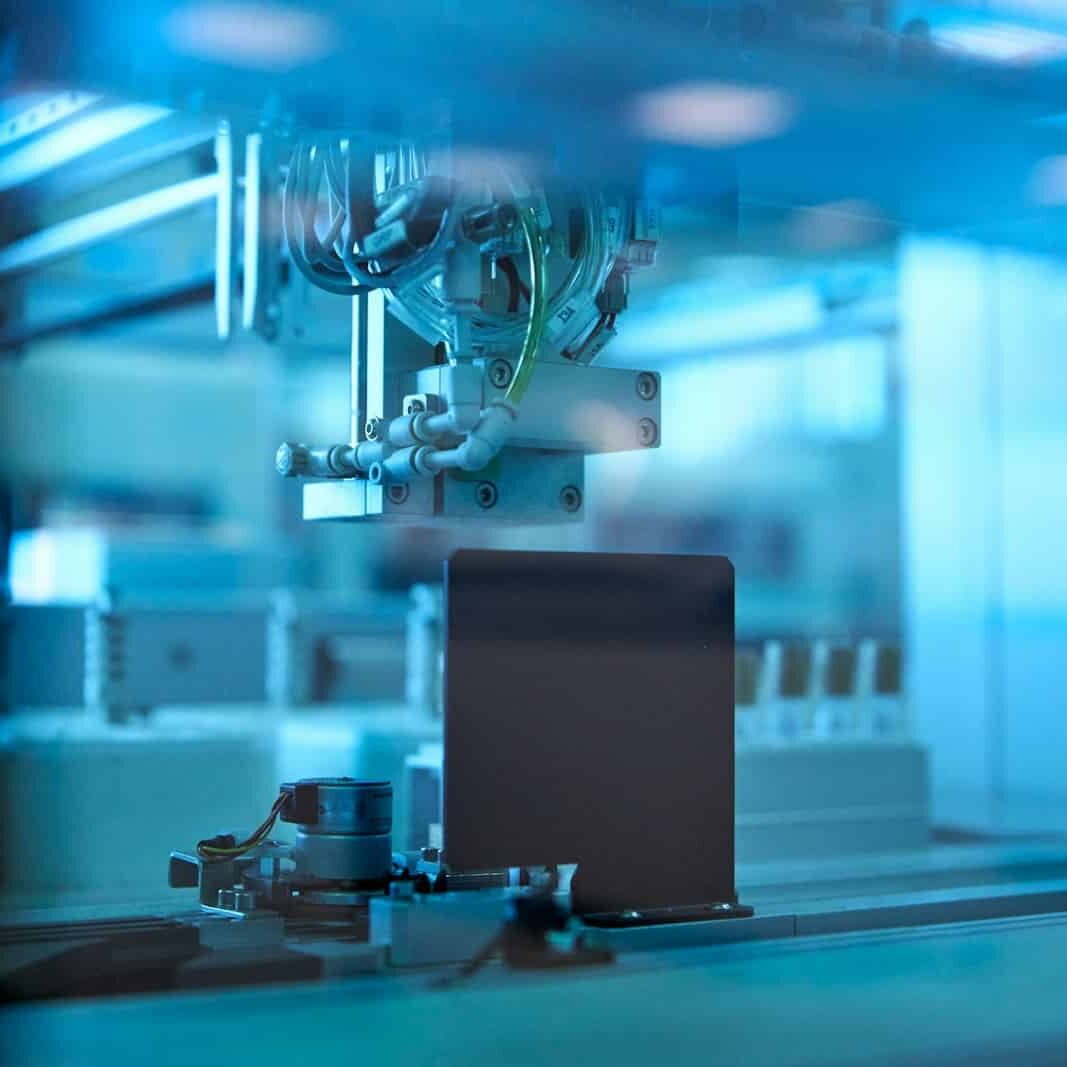

Pharmaceutical X-Ray Inspection Systems & Services

Recall prevention for the pharmaceutical industry.

Pharmaceutical and medical products are subject to a growing list of quality concerns and compliance requirements.

Manufacturers are under pressure to protect consumers and maintain profitability against increasing competition, making brand reputation of the utmost importance.

Our pharmaceutical x-ray inspection service is the fastest and most accurate method to detect physical contaminants and quality defects in pharmaceutical products, to help you ensure patient safety.

X-ray inspection for pharmaceutical and medical products can simultaneously detect contaminants, damaged and missing items or manufacturing faults in almost any pharmaceutical product and many forms of packaging.

Complete Cases

Turnaround

We offer fast and cost-effective pharmaceutical x-ray inspection service

We may be able to inspect the product when it is in a case or carton format, depending on the quality issue or contaminant and the size / homogeneity of the product itself.

Non-invasive inspection

See inside without unpacking or disassembling the goods

Glass-in-Glass Detection

Find glass even within glass packaging

ISO 9001 certified

Accredited for our Quality Management System

Certified since 1999

Europe’s first ISO-certified X-ray inspection service

What can our pharmaceutical x-ray inspection system detect?

AIS’ pharmaceutical x-ray inspection system can rapidly and accurately detect many common quality concerns:

- Missing or broken tablets in blister packs

- Missing instruction leaflet or components

- Incorrectly assembled medical devices or incomplete packs

- Small metal and glass fragments, even within glass containers

- Contaminated medical dressings

- Items trapped in security seals

When an incident occurs, AIS will provide an immediate response and evaluation.

Our advanced x-ray technology can be configured to find sub-millimetre stainless steel fragments, even in items containing metal parts, or detect damaged containers, under-fill or an incomplete box of tablets within a case of items.

Effective quality assurance for the pharmaceutical industry

We will help you ensure continuity of quality standards when a CCP has failed. We can manage a potential recall crisis when the need arises, or provide routine quality checks at a simple per-unit cost.

Our x-ray inspection service is always confidential and our highly trained technicians will put your product safely back on the market as fast as possible.

Why choose our pharmaceutical x-ray inspection service?

Pharmaceuticals FAQs

What is a GMP inspection?

Good manufacturing practice (GMP) is the minimum standard that a medicines manufacturer must meet in their production processes.” Gov.uk

AIS do not provide “GMP inspections” but our x-ray inspection service will help pharmaceutical manufacturers to meet the consistent quality requirements of GMP.

Pharmaceutical inspection can provide additional assurance for patient safety as well as improve processes and brand integrity, and assist you in gaining compliance.

Please contact us for a fast and confidential assessment for your particular pharmaceutical products.

What types of packaging can AIS inspect?

Pharmaceutical, medical, home and personal care products can be packaged in an unlimited list of packaging types including cartons, boxes, bottles, tubes and sachets. Products can be in multi-packs, elaborately packaged bottles, boxes and gift sets, vacuum packed and security sealed.

Our x-ray inspection systems can be configured to inspect each of these, whether packaged in metal foil and composite materials, glass packaging or even full cases of products.

We can also inspect electronic medical devices and personal care items, food and many other products.

What type and size of things can AIS detect?

As a general statement, x-ray can identify anything which has a reasonable absorption differential to the product in which it is surrounded. Typically, we detect foreign objects such as metal and glass fragments or higher density plastics and rubber compounds.

The size of object that we can identify is influenced by the density and size of the contaminant and the product, the position of the contaminant within the pack, and the type of packaging.

Detection of missing items and quality concerns is subject to similar factors.

Find out more about our highest resolution scanner, the Micron Scan.

We will always give a clear and honest appraisal of what is achievable and be prepared to demonstrate that to you at any time.

Request a Free Sample Inspection for AIS to evaluate your product and problem.

How long does it take to inspect the product?

The inspection time is dependent on the target defect or contaminant, the product and pack size, if it can be inspected in a case or has to be stripped from the case, re-shrunk wrapped etc.

A pallet can be as quick as 5 minutes or as long as two hours.

Request a Free Sample Inspection for AIS to evaluate your product and the likely timescale required for your particular problem.

You can also call us – we can often evaluate the issue on the phone.

Is the x-ray equipment for hire?

Yes, some of our customisable x-ray inspection systems and metal detectors are available to rent at your premises. These can be hired, subject to availability, on flexible contract periods – usually for an immediate or short term requirement.

Find out more about X-Ray Inspection Equipment Hire.

Request free sample inspection

Free, immediate and confidential evaluation

Email Us

sales@aisx-ray.com

Call Us

+44 (0)1933 674030

Opening Hours

8am to 5pm – Monday to Friday (GMT)